In today’s rapidly evolving technological landscape, 3D vision systems have become indispensable across various industries. These advanced systems enable machines and robots to perceive and understand the three-dimensional world, opening doors to unprecedented levels of automation, precision, and efficiency.

This article will explore what 3D vision systems are, how they work, their applications, advantages, challenges, and future trends. Whether you’re an engineer, a business owner, or a tech enthusiast, understanding 3D vision systems is key to leveraging the next generation of smart technologies.

What Are 3D Vision Systems?

3D vision systems refer to technologies that allow machines to capture, interpret, and analyze three-dimensional information from the surrounding environment. Unlike traditional 2D cameras that only capture flat images, 3D vision systems provide depth perception, shape, and spatial data. This capability enables machines to “see” in a way similar to human vision but with higher accuracy and repeatability.

These systems typically consist of hardware components such as 3D cameras or sensors, illumination sources, and processing units combined with sophisticated software algorithms for image reconstruction and analysis.

How Do 3D Vision Systems Work?

At the core, 3D vision systems use various techniques to capture spatial data:

1. Stereo Vision

Stereo vision systems use two or more cameras positioned at different angles to capture images of the same object. By comparing these images, the system calculates depth information, similar to how human eyes perceive depth.

2. Time-of-Flight (ToF) Cameras

ToF cameras emit light pulses and measure the time it takes for the light to bounce back from objects. This travel time is converted into distance measurements, creating a depth map.

3. Structured Light

Structured light systems project known light patterns onto an object and analyze the deformation of these patterns to reconstruct 3D shapes.

4. Laser Triangulation

This method involves projecting a laser beam onto an object and capturing the reflected light from a different angle to measure distances accurately.

These techniques provide rich 3D data, allowing systems to generate detailed point clouds, meshes, or depth maps for further analysis.

Key Components of a 3D Vision System

- 3D Cameras/Sensors: Capture spatial data using one or more of the methods described above.

- Illumination Sources: Provide the necessary light, often lasers or LED projectors, to improve data quality.

- Processing Unit: Computes depth and reconstructs 3D models from raw data.

- Software Algorithms: Perform object recognition, measurement, inspection, and decision-making.

Applications of 3D Vision Systems

The versatility of 3D vision systems has led to widespread adoption in many industries:

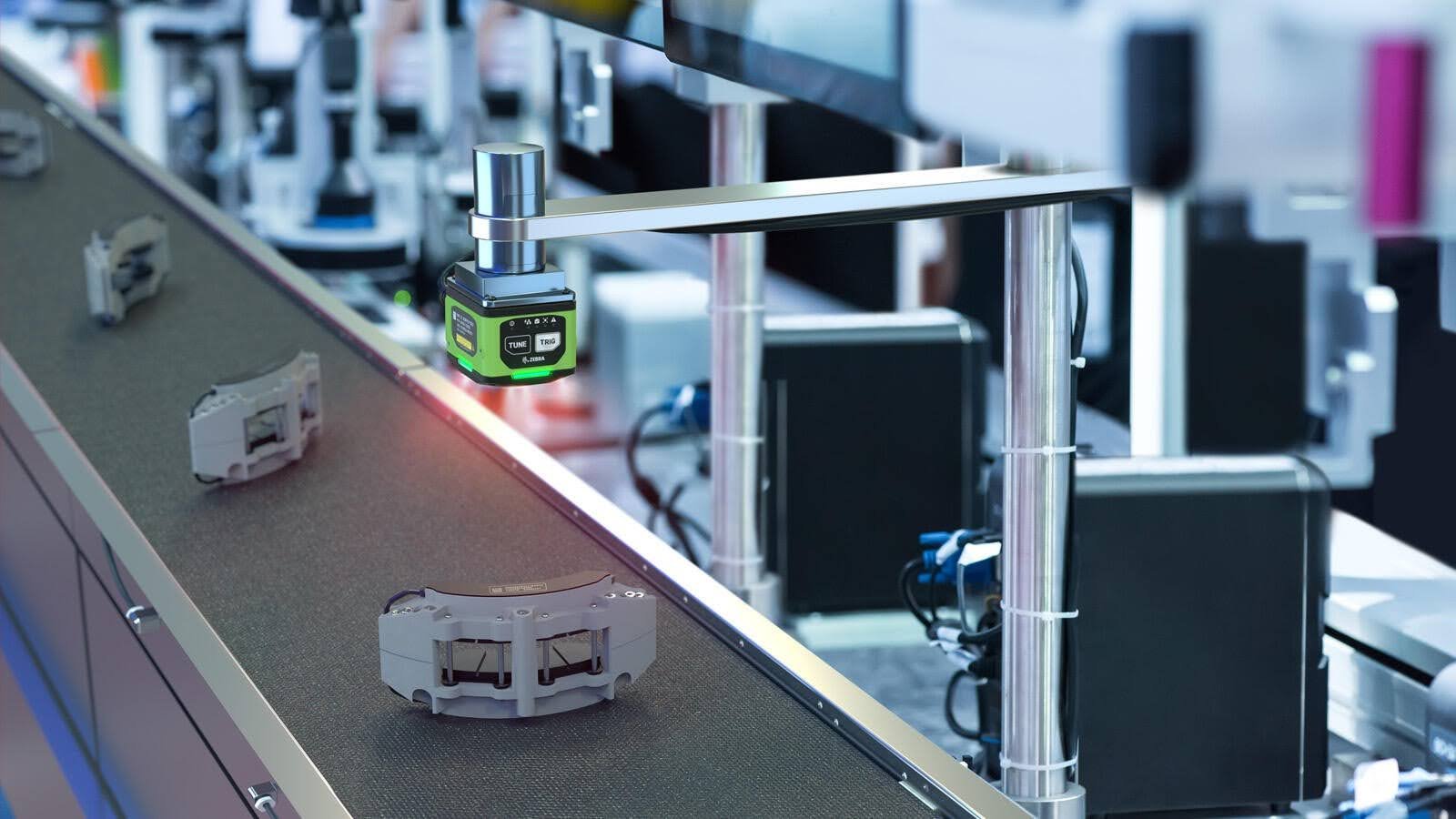

Manufacturing and Quality Control

3D vision systems enable precise inspection of products on assembly lines, detecting defects, measuring dimensions, and guiding robotic arms for assembly tasks. This ensures higher product quality and reduces waste.

Robotics and Automation

Robots equipped with 3D vision can navigate complex environments, handle objects of varying shapes, and perform tasks such as picking and placing with remarkable accuracy.

Automotive Industry

From autonomous vehicles using 3D vision for obstacle detection to precision manufacturing of automotive parts, this technology plays a crucial role in safety and production efficiency.

Medical Imaging and Surgery

3D vision enhances imaging techniques and assists in surgical planning and robotic surgery, offering greater precision and better patient outcomes.

Agriculture

Agricultural robots use 3D vision systems to monitor crop health, estimate yield, and perform automated harvesting.

Security and Surveillance

3D vision improves facial recognition, intrusion detection, and perimeter security by providing detailed spatial awareness.

Advantages of Using 3D Vision Systems

- Increased Accuracy: 3D data offers precise spatial measurements beyond 2D limitations.

- Enhanced Automation: Machines can perform complex tasks with minimal human intervention.

- Improved Quality Control: Detects even minor defects that 2D systems might miss.

- Greater Flexibility: Adaptable to different industries and applications.

- Cost Savings: Reduces labor costs and material waste through efficient processes.

Challenges and Considerations

Despite their benefits, 3D vision systems come with challenges:

- High Initial Investment: Advanced hardware and software can be costly.

- Complex Integration: Requires skilled engineers to integrate with existing systems.

- Data Processing Demands: 3D data is large and requires powerful processors.

- Environmental Sensitivity: Performance may degrade under certain lighting or reflective conditions.

Choosing the Right 3D Vision System

Selecting a 3D vision system depends on your application needs. Consider these factors:

- Resolution and Accuracy: Determine how detailed and precise your measurements need to be.

- Speed: Some applications require real-time processing.

- Environmental Conditions: Choose systems that can operate reliably under your specific conditions.

- Budget: Balance performance needs with cost constraints.

Future Trends in 3D Vision Systems

As technology advances, 3D vision systems are evolving rapidly:

- AI Integration: Artificial intelligence enhances object recognition and decision-making.

- Miniaturization: Smaller, more affordable sensors enable broader adoption.

- Improved Data Processing: Edge computing allows faster, on-site analysis.

- Expanded Applications: Emerging fields like augmented reality (AR) and virtual reality (VR) rely heavily on 3D vision.

Conclusion

3D vision systems are transforming industries by providing machines with a deep understanding of their environment. This technology’s ability to deliver precise, real-time 3D data drives smarter automation, better quality control, and new possibilities in healthcare, agriculture, and beyond.

Investing in the right 3D vision system can unlock new efficiencies, improve safety, and offer competitive advantages in today’s tech-driven market. As costs decrease and capabilities expand, the adoption of 3D vision will only accelerate, shaping the future of machine intelligence and automation.